Your partner in providing static process equipment for high impact industries

We deliver turnkey solutions to most demanding industries, starting from design and engineering to documentation, delivery and installation. We work closely with you along the way, and take the needed role to achieve the results that your industry and case demand. Estanc’s operations are based on our core values:

People

We contribute to dedicated leadership, employee and customer satisfaction, happy families and strong partnerships.

Passion

We care. We are committed. We truly enjoy what we do.

Purpose

It is important for us that everything we do is purposeful.

Process

We believe in process-based operations that support the achievement of our objectives.

Industries we serve

By far our largest project sector

We have engineered and manufactured equipment for the major pulp and paper factories all over the world, delivering several dozen devices to each factory.

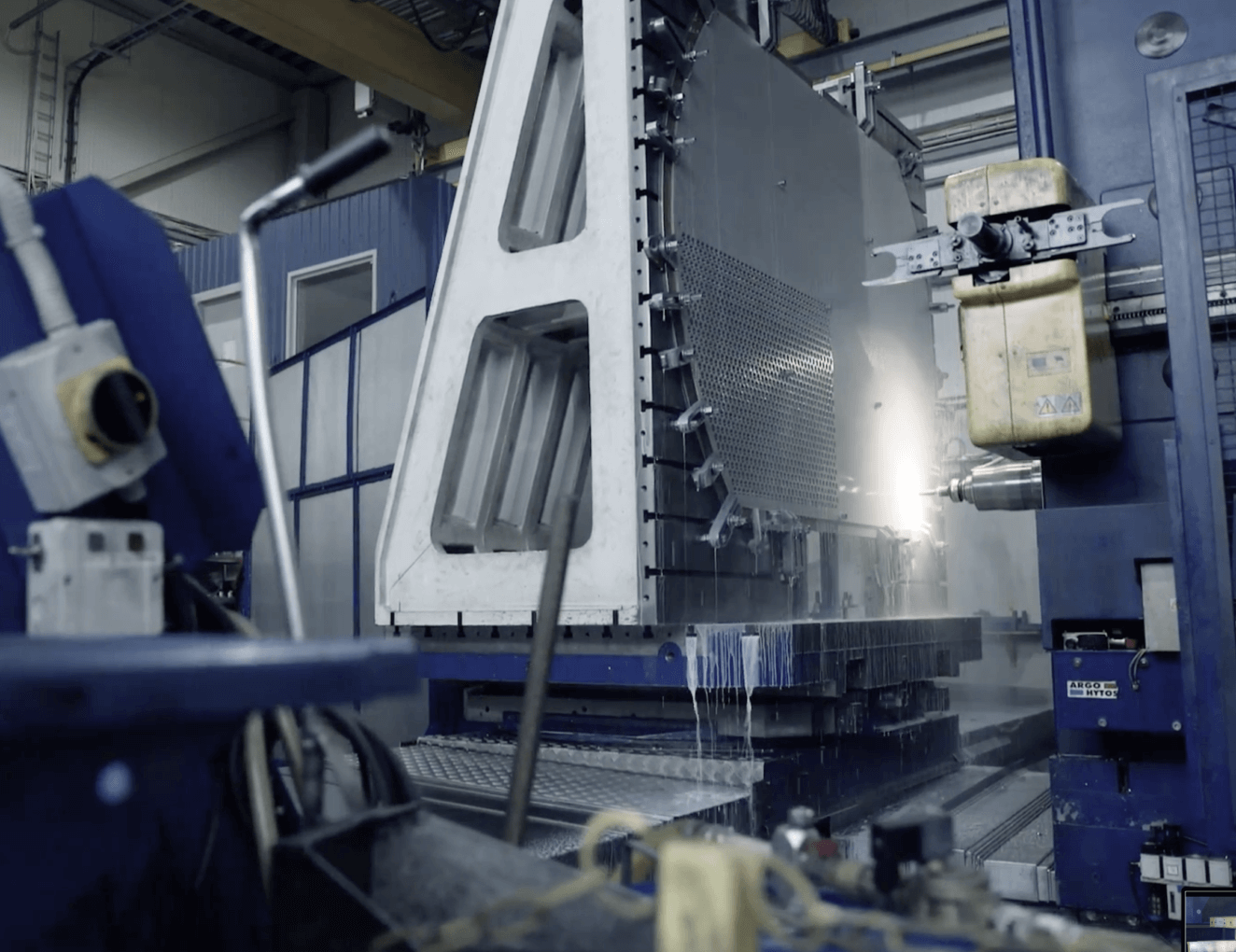

Top of the class production facility

From first contact up to delivery and installation

thought through operations

dedicated employees

different sectors served

years of experience

About the team

Who we are

We are passionate and cooperative team, who is eager to do better every day.

What we value

We want to be an integral part of building a sustainable and prosperous world.

Join us

We offer the possibility to work in a modern and agile manufacturing company, where each individual’s ambitions are valued.

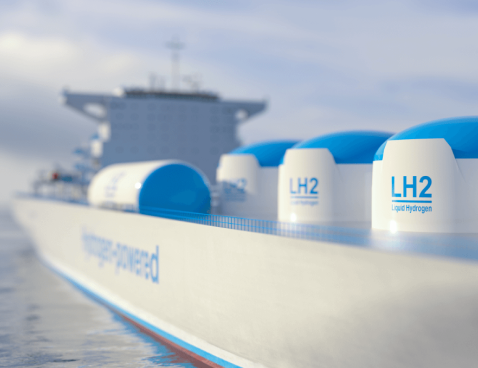

Sustainable processes are in our DNA

We focus our efforts on areas where we deliver the greatest positive impact. Considering that our products help to contribute to the alleviation of some of the industry’s and world’s greatest sustainability challenges.